New Well Drilling

Our first step in the construction of a new well is to pick the location of the well. There are various factors that determine where the well can be drilled, including maintaining certain distances from the septic system, allowing sufficient space for the drilling rig and service truck, avoiding overhead obstructions, and accounting for flow of the drilling fluids away from the well. These factors can be explained in greater detail upon request.

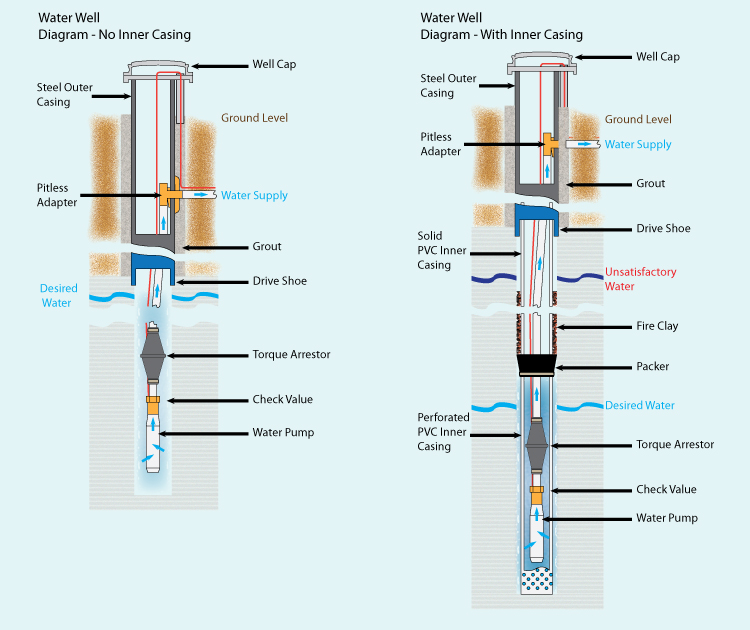

Our new wells are drilled with an air rotary rig, and when required, we bring in a cable tool rig to develop the well’s flow and/or set an inner casing. The air rotary is initially used because of its efficiency. It can set the steel casing and drill most wells to their required depth in one day. We typically use steel casing over plastic because it can be drove ahead into the rock with the air rotary rig to form a better seal against surface water contaminating the well. It is also less susceptible to damage than plastic casing. Once the steel casing is set, we drill down until we find a satisfactory water flow.

If there are unsatisfactory water flows above the satisfactory one, then an inner casing is required to seal off the unsatisfactory flow(s). It is a PVC casing that goes inside the steel casing and sits on the bottom of the well. A packer is used to seal off the upper flow(s) of water. Clay is poured on top of the packer to ensure a good seal. Below the packer, the casing is perforated to allow the desired water flow to enter the well.